M.blue® & M.blue plus®

FEATURES

- ONE valve for the unique requirements of a life with hydrocephalus: mobility, growth, changes in the course of disease

- unique uncompromising pressure adaption to optimize individual patient needs

- smallest adjustable gravitational valve worldwide

- 2-in-1 technology: adjustable gravitational unit combined with fixed differential pressure unit in one valve

- protected against over-drainage through individually and continuously adjustable opening pressure from 0-40 cmH2O

- MRI-compatible up to 3 Tesla: no X-ray control after MRI necessary, no additional radiation exposure for the patient

- protected against unintentional adjustment by means of exposure to magnets found in daily life, such as those used in smartphones, toys, induction cookers or safety barriers at the airport

- Innovative M.blue plus Instruments for M.blue and proGAV 2.0

- Intuitive, safe and comfortable adjustment

- precise precision engineering

- robust and durable: made of titanium

M.blue® & M.blue plus®

FUNCTIONALITY

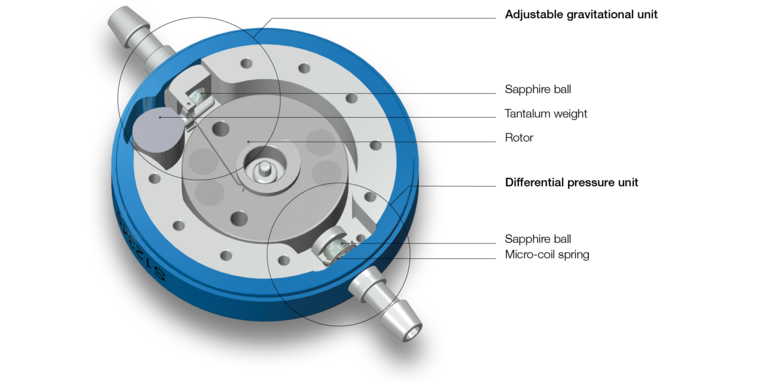

The M.blue is a position-dependent hydrocephalus valve. It consists of an adjustable gravitational unit and a fixed differential pressure unit.

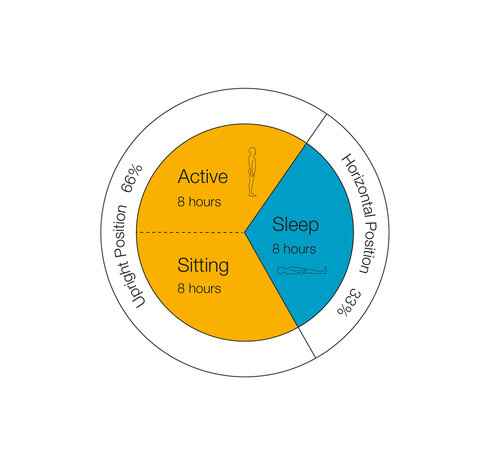

The combination of these two units ensures automatic adjustment of the opening pressure depending on the patient's body position and thus counteracts the risk of possible over-drainage complications, especially in the upright and active body position.

The M.blue is a hydrocephalus valve operating in a position-dependent manner. It consists of an adjustable gravitational unit and a fixed differential pressure unit.

The combination of these two units ensures automatic adjustment of the opening pressure depending on the patient's body position and thus counteracts the risk of possible over-drainage complications, especially in the upright and active body position.

Particularly challenging and difficult forms of hydrocephalus require a much greater flexibility in treatment. This is what the M.blue plus stands for: a combination of an adjustable gravitational unit and an adjustable differential pressure unit (proGAV 2.0).

Both M.blue variants are made of robust and biocompatible titanium and are the result of precise precision engineering.

The differential pressure unit in the M.blue is available in the units 0, 5, 10 and 15 cmH2O. The selected opening pressure of the differential pressure unit is equally effective in all body positions. When lying down, the differential pressure unit acts alone and usually has a low selected opening pressure, so that the valve drains brain water as needed when the brain pressure increases during sleep and rest phases. A microspiral spring that presses a sapphire ball into a ball seat is responsible for maintaining the correct pressure. If the brain pressure rises above the selected opening pressure, the spring gives way, the differential pressure valve opens and allows brain fluid to pass through until the brain pressure has dropped again accordingly.

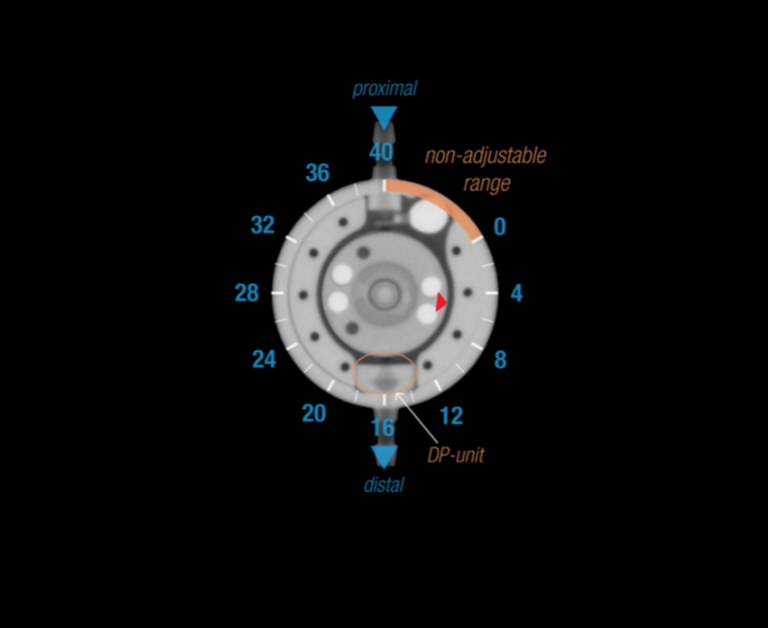

The gravitational unit in the M.blue is adjustable from 0-40 cmH2O and is only active in the upright body position. Now the sum of both units - gravitational and differential pressure unit - determines the total opening pressure of the M.blue. The more upright the patient is, the higher the opening pressure of the M.blue. The considerably higher opening pressure in the active phases of the day is particularly important because hydrostatic and hydrodynamic phenomena in the shunt system take effect in the upright body position and there is otherwise a risk of overdrainage.

The opening pressure of the gravitational unit is determined by a combination of rotor, rod spring, tantalum weight and sapphire ball. The tantalum weight holds a sapphire ball in the ball seat via a lever, which closes or opens the valve. Depending on the body position of the patient, the influence of a tantalum weight on a sapphire ball changes and thus the valve opening pressure. The preload of the rod spring connected to the lever can be adjusted via a rotor using the M.blue plus Instruments and can influence the desired opening pressure.

M.blue® & M.blue plus®

VALVE ADJUSTMENT

The unique "Active-Lock" mechanism protects the M.blue against unwanted adjustment due to the influence of external magnetic fields and makes the M.blue compatible for MRI examinations up to 3 Tesla. This eliminates the need for X-ray control after MRI imaging and protects the patient from additional radiation exposure. Only an active pressure on the valve diaphragm releases the rotor brake and makes an adjustment possible. Thanks to the built-in tactile feedback mechanism, this can usually be felt and heard by a click, thus giving the doctor the necessary feedback and assurance that the applied pressure is sufficient for an adjustment. As long as pressure is not applied directly to the valve diaphragm, it remains safe from unintentional adjustment.

Learn more about our M.blue adjustment tools:

About the tools

M.blue® & M.blue plus®

PRESSURE LEVEL DETECTION IN X-RAY IMAGE

The set pressure level of the M.blue can be reliably checked at any time with the M.blue plus compass without need for additional X-ray examination.

For recognition in the X-ray image, we recommend the use of the MIETHKE App. Here, the valve can be individually adjusted according to the X-ray image and the pressure level of the M.blue can be reliably read by means of a template (picture on the right: adjustable gravitational unit 20 cmH2O , differential pressure unit 15 cmH2O).

The selection of the appropriate pressure level of the M.blue depends on several factors, including the patient's age, degree of activity, height and stature. For further information, please refer to our recommended pressure level.

MIETHKE

Valve Board

Our Valve Boards

OUR MIETHKE PRODUCT FINDER

We consider the individual patient situation, surgical technique and treatment plan. The questions are designed in such a way that the list of results provides a maximum of three product recommendations.

![[Translate to English:] Zwei Marketing Mitrabeiter*innen blättern durch M.scio Prospekte von MIETHKE](/fileadmin/_processed_/f/8/csm_SalesTeam_a8fc997cce.png)

FOR OUR SALES EXPERTS

We are there for you!

Dear sales & shunt experts all over the world,

our toolbox is big. If you need something to make MIETHKE shunts easier to understand or have new ideas, please get in touch with us. We look forward to exchanging ideas and - who knows - maybe what you are looking for is already there and we can easily make it available to you. Or we can develop something with you that could also be very helpful for other markets.

Your MIETHKE Marketing Team

DO YOU HAVE ANY QUESTIONS ABOUT THE PRODUCT?

WE ARE THERE FOR YOU

OUR PARTNERSHIP

WITH B. BRAUN

B. Braun and MIETHKE - Together for a better life with hydrocephalus

We have a long and intensive partnership with B. Braun in the field of neurosurgery. We are driven by a common vision: to improve the lives of hydrocephalus patients around the world with innovative solutions.

Our partnership is an exciting combination of B. Braun's many years of expertise as one of the world's leading medical device and pharmaceutical companies and our agility as an innovative company and technology leader in gravitation-based shunt technology.

Our Strong Partner in Neurosurgery:

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/7/csm_Christoph_Miethke_M.blue_Forschung_und_Entwicklung_eac8c673db.jpg)

![[Translate to English:] Patientengeschichte_Julia_Teil2 [Translate to English:]](/fileadmin/_processed_/8/7/csm_Story-Teaser_Julia_Teil2_73fe7e118c.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/4/csm_csm_Christoph_Miethke_Mblue_Mblue_plus_a3f8f6ecb0_neu_081367769e.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/4/csm_MIETHKE_KarlsWaechter_Teaser03_neu_8f7ee0cf94.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/0/csm_MIETHKE_Msico_Teaser_neu_b1b52c7855.png)